AECOMIX-TAURUS

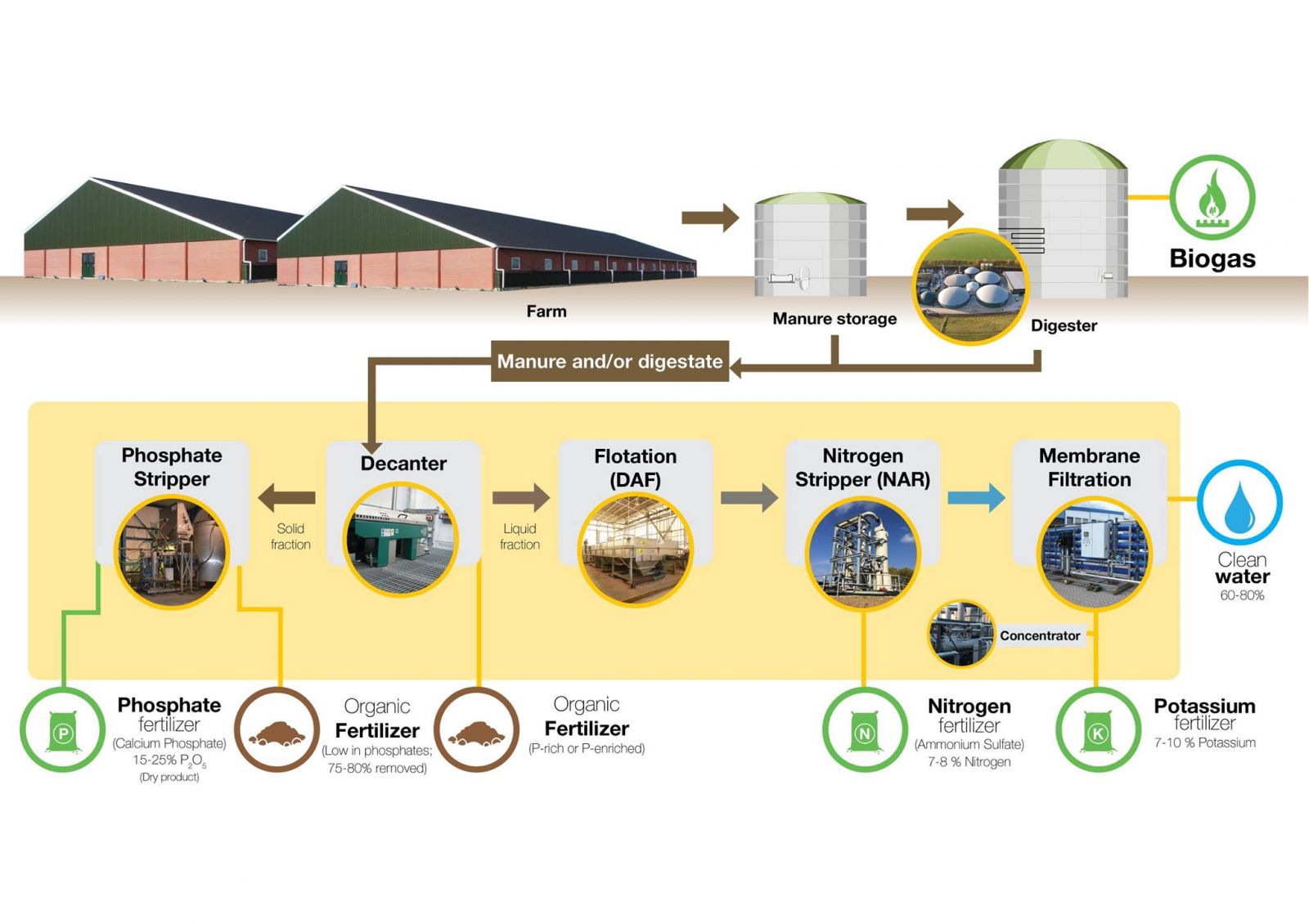

Nijhuis Water Technology нь ялгадас, хоол тэжээл, органик бохирдолыг боловсруулж, Агааргүй нөхцөлд хөдөө аж ахуйн хог хаягдал, органик бодисыг биогаз болон шингээж боловсруулдаг. Үйл явц дахь тэжээл нь дараахь зүйлээс бүрдэнэ.

- Амьтны ялгадас.

- Хөдөө аж ахуйн хог хаягдал.

- Хүнсний үйлдвэрийн хаягдал.

- Эрдэнэ шиш, эрдэнэ шиш, өвс, чихрийн нишингэ зэрэг хамтарсан субстратууд.

Боломжтой түүхий эдээс хамаарч бид хамгийн оновчтой системийг боловсруулж гаргах болно. Энэхүү системд дараахь үе шатуудыг багтааж болно: түүхий эд хадгалах, түүхий эд бэлтгэх, тэнцвэржүүлэх, холих систем, түүний дотор шингэрүүлэгч бодис, биогазын агааржуулалт ба хэрэглээ, шингэцтэй хатуу бодисыг ялгах, боловсруулах, боловсруулалт хийх.

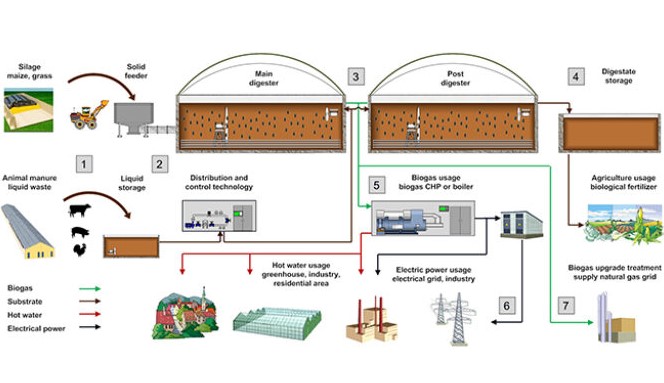

1. Raw material storage

a. solids materials: horizontal silo’s end/or storage containers

b. liquid materials: storage tanks

The required storage capacity is depending on the raw materials available for your plant.

2. Digester feeding systems

Solids materials are periodically fed to a bunker where the solid materials are pretreated and mixed before the are automatically transferred to the digester. Liquid materials are automatically pumped into the digester system.

3. Digester and optional post digester

a. Under anaerobic conditions the feed materials are digested / fermetated to create biogas with around 50-60% methane and 40-50% carbondioxide. To create an optimal amount of biogas and a stable system, The reactor is designed to operate at 38°C. The digester tank is equipped with a mixing and heating system.

b. For high loaded systems a post digester can be added to the design. In the post-digester the process continuous and the additional gas can be extracted.

4. Digestate

The fermentation residues from the digester and optional post digester is called digestate. Digestate is a high quality liquid fertilizer, which can substitute chemical fertilizers.

5. Combined Power and Heat (CHP) unit

A CHP unit is a motor that drives a generator to electricity and heat out of the created biogas. Energy can be used for operating the biogas plant and can be sent to the public network. The heat will be used to maintain the temperature in digester tanks and can be distributed for other purposes like heating of greenhouses, living areas, industry.

6. Electricity power supply

For the larger biogas plant the created energy needs to be transformed from 400V to 10,000V before connecting to the public network. For smaller plants this is not applicable.

7. Upgrading of biogas to natural gas

Instead of point 5 and 6 there is an option to upgrade the biogas to natural gas. Carbon dioxide has to be extracted from the biogas, before feeding the gas to the public natural gas network.

Advantages & Characteristics

Energy in a biogas plant is carbon neutral.

Biogas and energy can be produced 24/7.

Closed systems, low environmental smells.

Low dependence on energy from the public net and import from othercountries.

Energy generation is not directly depending on wind, water and sunconditions.

Biogas can be stored.

Fertilizer value of manure is improved by the biogas process.